يعتبر الفخار من الحرف اليدوية الدائمة التي يحبها الناس لجمالها الفريد وعمليتها. وسواء في الحياة اليومية أو في مجال جمع التحف الفنية، يحتل الفخار مكانة لا يمكن الاستغناء عنها. وباعتباره مصنع الفخار المحترفسوف نأخذك إلى فهم أعمق لعالم الفخار، بما في ذلك الأجزاء الأربعة التالية: بدءاً من تعريف الفخار، ثم طبقة التزجيج، ثم تركيبة الطين، وأخيراً عملية الإنتاج.

ما هو الفخار?

تسمى منتجات الطين الطبيعي عن طريق التشكيل والتجفيف والحرق بالفخار. وعادةً ما يتم حرقه عند درجة حرارة تتراوح بين 900 درجة مئوية إلى 1200 درجة مئوية لإعطائه صلابة ومتانة كافية. وبالمقارنة مع الخزف، يتميز الفخار بقوام أكثر خشونة بشكل عام مع كثافة تلبيد أقل، ويميل إلى اللون البني الدافئ أو الأحمر. يمكن استخدام الفخار ليس فقط في صناعة الأدوات العملية، مثل أدوات المائدة والمزهريات والحلي، ولكن أيضاً كوسيط فني مليء بالثقافة والشخصية.

ما هو الانزلاق في الفخار?

زلة الطين هي مادة شائعة الاستخدام في صناعة الفخار، وهي مصنوعة من الطين والماء. تُستخدم الزلّة في مجموعة متنوعة من العمليات، بما في ذلك التشكيل وتوصيل الأجزاء والتلوين. عادة ما يتم تعديل تركيبته ونسبه بشكل طفيف وفقاً للاحتياجات المختلفة. وتشمل الوظائف المحددة ما يلي:

الاتصال: في عملية صناعة الفخار، يمكن استخدام الانزلاق كمادة لاصقة لربط أجزاء الطين المختلفة معاً.

التلوين والزخرفة: يمكن إضافة أصباغ معدنية وتطبيقها على سطح الفخار لإثراء التأثير البصري.

الإصلاح والتسوية: يمكن أن يملأ الأسطح غير المستوية ويزيد من دقة سطح الفخار.

كم عدد طبقات التزجيج على الفخار?

الصقيل هو طبقة واقية وزخرفية على سطح الفخار. بعد الحرق على درجة حرارة عالية، يتم تزجيجها مما يجعل سطح الفخار أملس وسهل التنظيف، مع تعزيز مقاومته للماء ومتانته. يعتمد عدد طبقات التزجيج على الفخار على التصميم والمتطلبات الوظيفية:

طلاء زجاجي أحادي الطبقة: عادة ما يتم تطبيق التزجيج أحادي الطبقة على الفخار البسيط. وهو منخفض التكلفة وسهل التشغيل ومناسب للإنتاج بكميات كبيرة.

طبقة زجاجية مزدوجة أو طبقة زجاجية متعددة الطبقات: إذا كنت ترغب في الحصول على ألوان وتركيبات أكثر ثراءً، يمكنك وضع طبقة ثانية من التزجيج بعد جفاف الطبقة الأولى من التزجيج. يمكن أن ينتج عن تراكب طبقات التزجيج المختلفة تأثيرات فريدة من نوعها مثل التدرجات والتشققات. هذا طلاء زجاجي مزدوج الطبقات أو طلاء زجاجي متعدد الطبقات.

مزيج من التزجيج الشفاف والتزجيج الملون: بعض الفخاريات الفنية تقوم أولاً بوضع طبقة زجاجية ملونة ثم تغطيتها بطبقة زجاجية شفافة. يمكن أن يؤدي الجمع بين التزجيج الشفاف والتزجيج الملون إلى تعزيز طبقات اللون ولمعانه. ومع ذلك، فإن عملية التزجيج متعدد الطبقات هذه لها متطلبات عالية للعملية والتحكم في درجة الحرارة، ولكن التأثير البصري للمنتج النهائي رائع بشكل خاص.

كيف تبدأ في صناعة الفخار?

صناعة الفخار هي عملية إبداعية وتقنية تتضمن عادةً الخطوات التالية:

تحضير الطين: اختاري النوع المناسب من الطين (مثل الطين الأحمر والطين الأبيض)، واجعليه طرياً ولزجاً بعد التقليب والعجن.

القوالب: يمكنك استخدام العجن اليدوي والرمي والقوالب وغيرها من الطرق لتشكيل الصلصال بالشكل المطلوب. حافظ على يديك رطبة أثناء التشكيل لتجنب جفاف الطين وتشققه.

التجفيف: يجب تجفيف الفخار المقولب بشكل طبيعي، عادةً لبضعة أيام، لتجنب التشققات الناجمة عن التبخر السريع للماء.

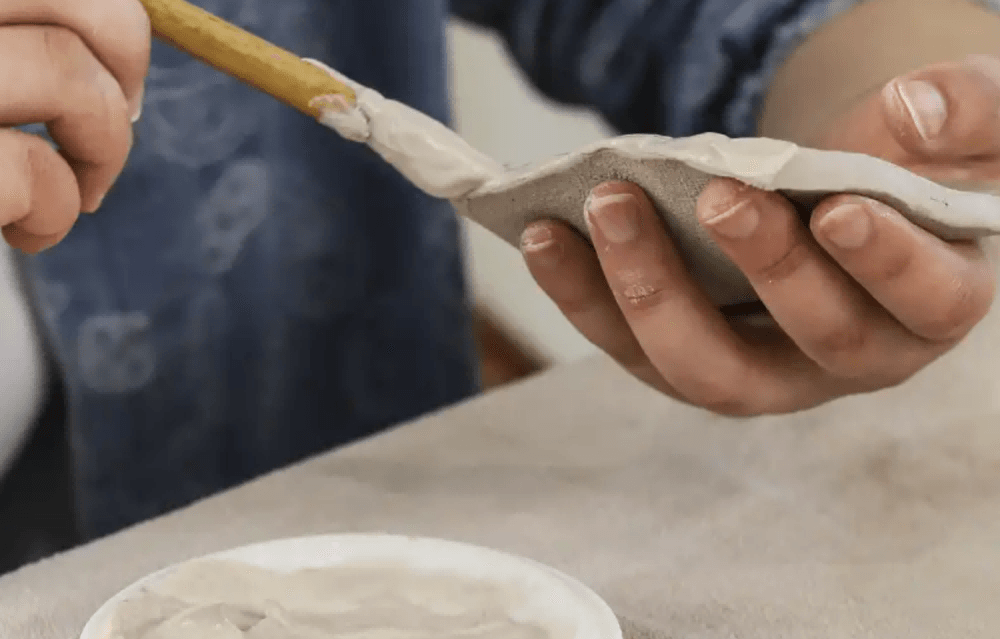

التزجيج: اغمس الفخار المجفف في ملاط التزجيج، أو استخدم الفرشاة والرش وغيرها من الطرق لتطبيق التزجيج بالتساوي على السطح. اختر طبقة طلاء زجاجية واحدة أو متعددة الطبقات وفقاً لاحتياجاتك.

إطلاق النار والخطوة الأخيرة هي الحرق على درجة حرارة عالية، وتعتمد درجة الحرارة والوقت على نوع الفخار والطلاء الزجاجي. بعد الحرق، سيكون للفخار بعد الحرق قوام صلب وسطح لامع.